Add to Cart

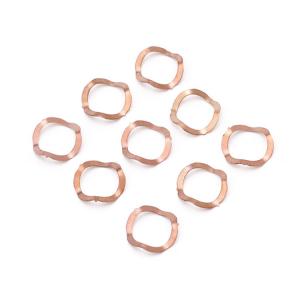

Customized Aluminum Alloy metal Die Mechanical Part Vacuum Casting

The Process of Vacuum Casting

Vacuum casting is a dependable and flexible process, capable of accommodating the development of complex designs. It's frequently used by companies for producing prototypes and other end-user product. For an excellent outcome in the casting process, it requires a high-quality master prototypical pattern.

Casting models are mostly created through stereolithographic, a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer-by-layer fashion using photopolymerization. It's important for the master model to be of high quality and perfectly designed, it will only transfer any flaws in the model to the final product or prototype. Using of high-end urethane casting service makes sure the model master in the picture is as it is in the first step towards a fine final product.

Once the model is well designed and got, it's inserted inside a two-part silicone mold and subjected to some very high temperatures. It cures after which the model and silicone mold is opened in a symmetric way. It creates a hallow area within the model exactly like the master model. The mold is then placed well inside a vacuum chamber hence the name vacuum casting.

While inside the vacuum chamber, they fill the required amount of material into the mold. The commonly used material for vacuum casting is urethane. Urethane casting is perfect for replicating design models, matching the needed characteristics for industrial grade material like glass- filled nylon, polycarbonate, and high-density polyethylene.

Upon filling the mold with urethane, so-called urethane molding, it's sealed. This is done using a high- intensity vacuum, to ensure they leave no air molecule inside. After the casting process, they open the mold, they can paint the prototype or produce as per the recommendation.

There two methods of getting a perfect model or design for your vacuum casting. One way to consider is CNC technology. This can provide parts of the highest accuracy, placing tight tolerance such as +/-0.05mm. But it takes longer to process, unlike SLA. The other way of getting a master pattern is the SLA. It's faster particularly on complex design or patterns, it's also easily combined in all internal 3D CAD input features.

| item | Precise Cnc Machining Service Stainless Steel aluminum 6061 cnc machining anodized aluminum part |

| Main products | 3d files design,3d printing,cnc machining,silicone mould,injection mould. |

| Type | Rapid Prototyping |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, abs,nylon,silicone,rubber. |

| Micro Machining or Not | Micro Machining |

| warranty | 1 year |

| production time | 3-5days |

| MOQ | 1 pcs |

| Place of Origin | jiangsu |

| QC | 100% Inspection |

| material | Stainless Steel,abs,aluminum,wood |

| Surface treatment | Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Application |

Medical Equipments & device electronics, electrical device |

Pictures